Based on the popular text and comic, planning and scheduling improve maintenance productivity and safety, reduce costs and downtime.

Planner class for Jordan Aviation, Amin, Jordan

Maintenance work suffers from low productivity because each job requires the integration of various competencies, materials, tools, access, and specific information. Planning, coordination, and scheduling manage these thousands of details to improve productivity, improve safety, and reduce cost and downtime.

This program is designed for:

Designed for intensive maintenance environments, including mining, utilities, factories, refineries, smelters, and process plants, as well as large facilities. Titles include Maintenance planners, planners in training, supervisors, and individuals responsible for managing the planning function.

In addition to schedulers, material coordinators, and maintenance engineers, who get involved in creating job plans. There is also an advantage to having representatives from operations and stores for their perspective and input.

Our promise for this program is that your planners will be conversant with the techniques and procedures of effective planning and scheduling. They will also be trained to coordinate the maintenance schedule with production control and operations. This new understanding will lead to more effective job plans and better scheduling.

Benefits from sponsoring this course in-house:

You and your team will learn:

Well-planned, properly scheduled and effectively coordinated jobs can be accomplished

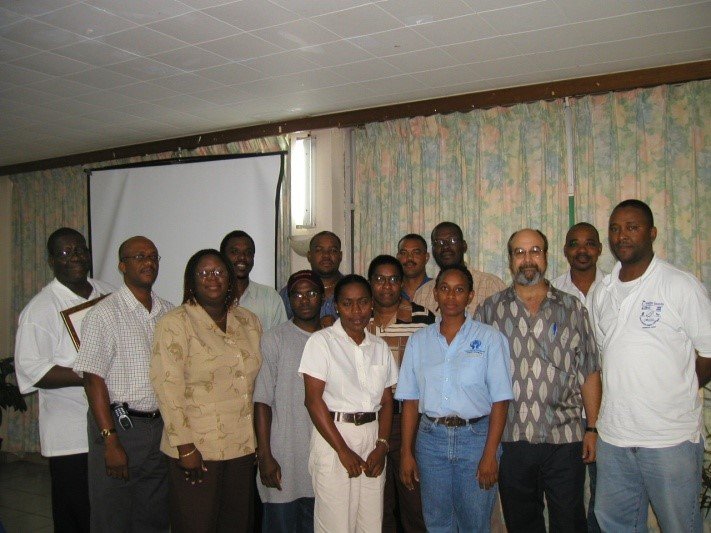

Planning and Scheduling class at Windalco, (bauxite mine) Mandeville, Jamaica

Also, a few extras like reduced parts usage and higher organizational morale (in production departments) are direct benefits.

Effective planning and scheduling also help increase the professionalism of maintenance efforts. In short, more work is completed more promptly, thereby improving customer service. It’s simple; you reduce wasted resources and save money.

Materials (one textbook, one comic book written for maintenance workers. Also, a complete workbook with supplemental materials and exercises

Virtual, Online configurations | Live, onsite |

5-18 contact hours | 9 A.M. to 4 P.M. with lunch and breaks |

5-Day 1-hour 5-Day 2-Hour 4-Day 3-Hour 4-Day 4-Hour 3-Day 6-Hour | 2-days 3- days 5-days |

Can be scheduled 1,2,3 sessions per week with homework | Contiguous |

Related courses: Shutdowns, Turnarounds and Outage Training

In the following agendas:

RED – Exercise with class involvement and discussion

BLUE—Case Study from Relevant industry

All sections will include discussions, case studies, exercises, and will consist of an activity to help plan your future direction.

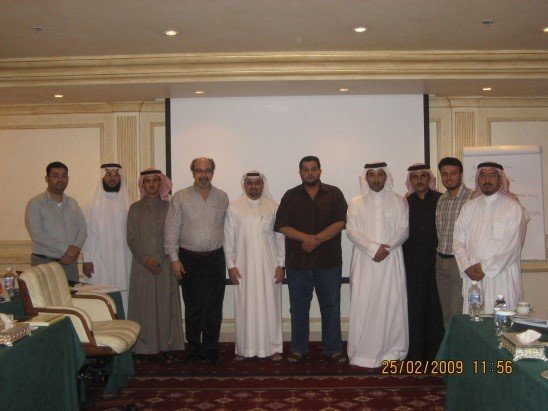

Planning and Scheduling for the Saudi Engineering Council in Dammam, Saudi Arabia

Planning Class at Windalco, Mandeville, Jamaica

o Planning Exercise construction estimates

· Complete the Planning questionnaire so that participants can evaluate their current planning operation against competent and world-class organizations.

· Evaluate the gap between what is happening and what would serve the organization’s long-term interests.

Maintenance Scheduling

· Scheduling (how is it different from Planning)

· Ready Backlog

o Validate backlog

o Rules to validate

o Common problems

Basics of Shutdowns, Turnarounds, and Outages

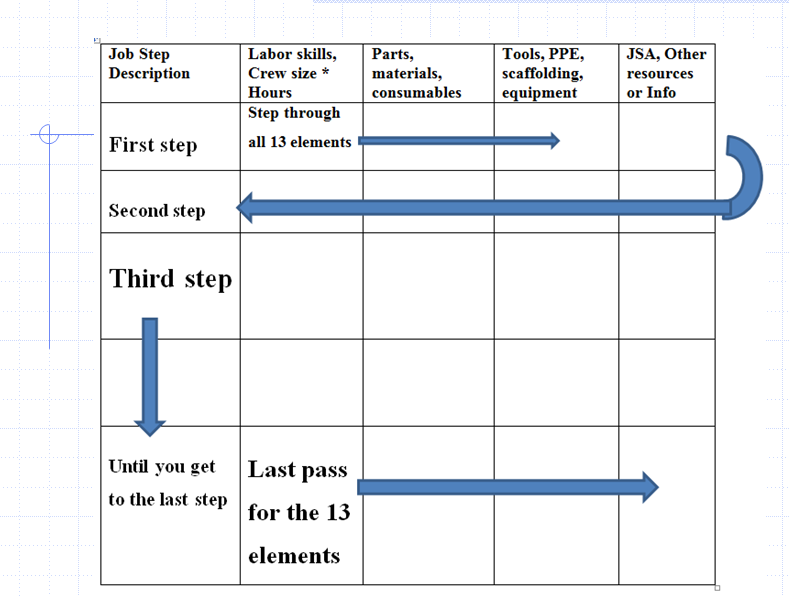

What is maintenance planning?

Where does Planning fit into Good Maintenance Practices?

Maintenance Management

Review of current practices

Backlog and backlog management

Work orders in support of planning and scheduling

Short discussion of the workflow with a job control function.

What are the conditions necessary for effective planning?

Review of current practices

Work Program

How and why to prepare the Maintenance Calendar

The coordination meeting between operations and maintenance

Scheduling

The way productivity increases (why does P/S work)

Scheduling uncovers problems in your operation

Jobs of the scheduler

PM systems to support Planning and scheduling

Job execution and feedback with job closeout and follow-up

Metrics and KPIs

Complete scheduling and coordination questionnaire so that participants can evaluate their own current planning operation against competent and world-class organizations.

Planning multiple jobs

Introduction to Project Management Techniques

Schedule and execution essentials

We are flexible about your specific needs for outcomes from the course.

The most basic way is to present a standard course after a brief email conversation about goals and objectives. The courses are tried and tested and have been used to good effect worldwide in many maintenance situations.

The second and most common option involves a one-day site visit before the class. This visit allows me to add examples from your facility, adjust the verbal presentation to suit your needs, meet some key players, and see some of the unique problems you face.

involves a more extensive site visit (to be defined) a few weeks before the class. This extra time allows me to customize and add examples from your facility and adjust the verbal presentation to suit your needs. It is always good to meet some of the key players and see for myself some of the unique problems you face.

The third option is to conduct a maintenance audit survey that looks at all the aspects of maintenance, evaluates areas where improvements are possible, and slanting the training to the competencies needed to implement the upgrades uncovered in the survey.