How to use the Internet to source parts, get specs, find vendors, ask questions, and do everything we take for granted now.

Based on popular text,

Vision for maintenance and the stockroom

Stores, effective procurement and part stocking are part of a World-class maintenance effort. The inventory system will support it with tight management of costs and investment and appropriate service levels.

Introduction :

Parts comprise 40%-65% of the money spent by the maintenance function. Stores is an area where appropriate management and computerization will pay enormous dividends in lowering costs and improving service levels.

Lack of spare parts is the single most significant contributor to low maintenance productivity and unnecessary downtime. This class introduces management techniques to mitigate these common problems.

In this intensive training, the student will consider inventory and spare part management and current ideas and strategies.

Who Should Attend

Senior and middle-level executives from Operations & Maintenance, Materials, and Finance. Storeroom managers, parts clerks, storeroom trainees, purchasing agents and buyers, and maintenance planners. There is also an advantage to having maintenance supervisors, maintenance engineers, and a representative from operations for their perspective and input.

Who Should Attend

Our promise for this program is that the students will be conversant with effective maintenance storeroom management and inventory control. They will be able to cut the number of SKUs, reduce the number of stockouts, and reduce the overall inventory level

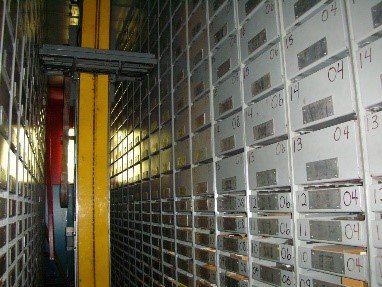

Maintenance parts warehouse with picking system

Basics

The economic stockroom

The Physical storeroom

Computerization

Dealing with the part itself

Business

Methods used

Maintenance, logistics, managers, and engineers come to this class with various backgrounds and learning styles. Attendees are encouraged to share their knowledge and experiences with others. To suit a range of learners, we will use: Lecture to cover basic information, Discussion to evoke questions, Case studies, Exercises, Small group assignments, Student presentations, Photographs, drawings, charts

Virtual, Online configurations | Live, On-site |

6-18 contact hours | 9 am to 4 pm with breaks for lunch and meals |

1- 6 Hour 4 Day 3-Hour 5-Day 2-Hour | 1- Day 3- Days |

Can be scheduled 1,2 sessions per week with homework | Contiguous |

Related courses:

Agenda for 1-day course

Module 1: Vision and overview for the stockroom and the spares stored there

Exercise: How is your inventory managed?

Module 3: The Economic Stockroom

Exercise: Calculate EOQ and safety stock

Module 2: The Physical Stockroom

Exercise: The 1-hour audit

Module 4: Dealing with the Part itself

Exercise: Manage you inventory with the end in mind

Wrap up and action plan

Agenda and schedule for 3-Day live course

Day 1

Day 2

Day 3

How to use the Internet to source parts, get specs, find vendors, ask questions, and do everything we take for granted now.

This new edition of a classic educates readers about the globalization of production and the changing of the guard of maintenance leadership, providing practical solutions to aid in these areas. Comprehensive discussions of potential problems and new opportunities, what bosses want, specifics for improvement of maintenance and production, world-class maintenance management practices, quality improvement, process aids, interfaces and strategies, personal and personnel development strategies

Well-planned, adequately scheduled jobs accomplish more work, more efficiently, and at a lower cost. This handy reference focuses on the groundwork that leads to the most effective utilization of maintenance resources. This book is a vital training document for planners, an educational document for management, and a valuable guide for those who interface with the planning and scheduling function and depend on the many contributions of planning and scheduling operations.

In its second edition, this comprehensive and easy-to-understand resource reviews all the significant discussions going on regarding the management of maintenance. It’s the perfect reference for maintenance professionals, providing quick updates on every specific maintenance management subject.

This long-awaited work organizes the details of a maintenance shutdown into manageable segments by introducing the steps needed for a successful shutdown or outage. Loaded with examples from many industries and actual events, this book provides valuable and practical guidance for maintenance managers, project engineers, supervisors, maintenance engineers, and planners working in any heavy maintenance environment.

A culmination of 20 years of research, teaching, and consulting, this book shares the best practices, mistakes, victories, and essential steps for success gleaned from working with organizations around the world. Unlike other books that only focus on the engineering issues (task lists) or management issues (CMMS), this in-depth resource is the first to emphasize the four aspects of success in preventive maintenance systems: engineering, management, economic, and psychological.

Lean Maintenance is written for leaders in maintenance, storeroom, or production. A practical book, Lean Maintenance, takes the reader on a journey, uncovering sources of waste, designing projects to address inefficiencies, selling projects to management, and delivering project results. Every area in maintenance is covered, including your TPM effort, storeroom, PM tasking, work orders, and computer systems. Readers put these ideas to work right away, immediately saving money, energy, and time!

This book is a new look at implementing Total Productive Maintenance (TPM). The book considers the economic upheavals of recent years. It demonstrates that TPM is less about moving maintenance tasks to operations than moving accountability for aggregate output of the plant to operators. Practical TPM requires a radical difference in management’s view of the worker and a drastic change in the way workers view their role.

This book is a comprehensive look at the management necessary to run a fleet in today’s environment. It includes audits, worksheets, ideas for all aspects of fleet maintenance. Topics include life cycle costing, storeroom management, shop layout, supervision, CMMS, budgeting, PM, and other essential issues. It is written for new managers and people in training for that position and directors responsible for fleets.

Facilities management is a broad discipline that considers architectural, construction, engineering, administration, and social skills, particularly for running and maintaining commercial, institutional, academic, and industrial buildings. This book will cover the essential roles. The book contains excellent, ready-to-use assessment forms and resources for comprehensive practical information.

The maintenance spare parts business is in turmoil. There have been fundamental changes in the sale, distribution, and storage of spare parts needed to maintain machinery and other physical assets. The key to uptime in manufacturing is managing risk and Surviving the Spare Parts Crisis: Maintenance Storeroom and Inventory Control by Joel Levitt describes how to evaluate risk in the inventory.

His latest book shows how the maintenance department can better support purchasing agents and buyers. It provides dozens of ideas to properly reduce inventory, reduce usage, and save money in parts, all while maintaining service levels

Companion book with the meetings textbook above. A model will improve time usage and time understanding. It helps maintenance professionals better use their time and get more done.

This book will improve your meetings by impacting specific areas, including preparation, participation, facilitation, logistics, and follow-up. Improving your meeting expertise will make you more valuable to your organization, be more productive, and feel better about your contributions. Meetings are everywhere in modern organizations because no one has found a better way to get business done. Yet, people who attend or facilitate meetings also complain that they are wasteful, de-energizing, and demotivating.

Compilation of 15 years of essays on maintenance management issues. The book is sorted by topic and is annotated with current observations. Great to see how some of the most critical new conversations are, in fact, quite old.

Quest for Defect Elimination is a full-color graphic novel that provides the basics of defect elimination and shows the Quest to achieve fewer defects. Fewer defects mean better quality, better yield, higher energy efficiency, and fewer machine breakdowns in the manufacturing world. In the world of equipment maintenance, fewer defects lead to fewer failures and higher reliability.

The Battle for Reliability is a graphic novel teaching the industry’s critical need to focus on maintenance fundamentals to avoid unscheduled shutdowns from breakdowns. It shows that even with the current focus on hi-tech sensors and software, everyday failures are still killing productivity. This easy-to-read book shows how creativity can solve repetitive reliability problems. In the end, ideas for projects generated from the rank and file can inexpensively and quickly improve reliability.

PM (Preventive Maintenance) is the primary way to ensure the reliability of machines, buildings, or other physical assets. Even the most rigorous reliability techniques such as RCM and PMO, in the end, rely on effective PM.

In a series of interesting anecdotes, Stories of PM tells the PM person the why, what, when, where, and even sometimes how to PM effectively. The stories are fun to read and contain descriptive color drawings. Stories of PM tells the whole story of PM, including the history and a couple of fun stories. Included are about a dozen best practices disguised as the rantings of a bug.

What stands in the way of quality maintenance work? Quality of work depends on everything going right. For years we’ve tended to blame the maintainers when quality suffers. Now we realize there are barriers to quality, independent of the person. These barriers are named and, when addressed, will improve the quality of your whole maintenance effort.

How do we get our people to take lubrication seriously?

Lubrication is the simplest and most effective way to ensure the smooth running of your equipment. Yet, many people don’t understand what they are doing, how to lubricate correctly, and why they are doing it.

In the past, a senior person would mentor new employees and teach them what, why, and how. Who has time now to introduce the new people to the ins and outs of lubrication? Lubrication: The Key to Machine Immortality takes on this job in a fun and exciting way with pictures and stories. It wrestles with advanced concepts in a fresh, clear, and entertaining way. It is the kind of book that new people will want to read.

| This book is one of the few resources for supervisors and floor maintenance leaders. It introduces the skills and knowledge to deal with supervisors’ myriad issues. Supervision is a leveraged activity. When we develop the supervisor’s skills, we enhance the productivity of the whole workgroup. This book provides valuable skill training for supervisors, team leaders, and managers. It offers techniques at the supervisor level to improve reliability. It teaches both the science and the art of the supervision of maintenance workers, discusses managing meetings and time, the elements of technical issues, and presents management and people skills, offering maximum productivity and high-quality provision of services and improving at the same time morale throughout the workforce. |

What organizations say about Joel Levitt’s Maintenance training.

“I have found Joel Levitt to be the most realistic and practical trainer I know. He can relate with the whole facility from the shop floor to the boardroom.”

Steve Lindborg, Holcim (US) Inc. GM Theodore Plant

Dear Joel;

I have attended many maintenance training courses, but none made the maintenance concepts so easy to understand and quite possible to adopt. We had a great time enjoying the way you delivered the message. I heartily wish you all the best.

Chief Operation Officer Ali O M Adam TADCO Saudi Arabia

Follow up note Ali O M Adam:

Lots of thanks for this effort. This class will help a lot in the implementation process. Already we formed a follow-up committee for the training concepts implementation. The points you highlighted will be given enough attention to grant smooth implementation.

I appreciate your great assistance that spotted a light towards many dark areas in our maintenance activities. Showing others how to do things right in a friendly way is a great value, rare to find in today’s world.

BEST REGARDS. Ali O M Adam

“My entire Maintenance department has changed for the better because of what I have taken from these classes.”

John Mullinax, Maintenance Manager, AXSYS Technologies, Inc.

“Extremely experienced & Knowledgeable Facilitator. Real-life pertinent examples. “

Nicole Kalloo of Nealco Properties Trinidad

“THANKS TO JOEL LEVITT” from REUBEN PARIAG see below:

Dear Mr. Pariag,

I am pleased to inform you that you have passed the Planning and Scheduling examination taken on 27th November 2009 at the University of the West Indies St. Augustine Campus scoring a total of 92%…

“The program makes you a better Maintenance person. “

Henri Gau–Gau of Maritime Authority Trinidad

The instructor obviously very knowledgeable in the field and communicates effectively. “

Kayode Martin of T&TEC Trinidad

Good content, very practical application to our maintenance practices.

Raffie Musaib Ali of Powergen Trinidad

“It was interesting to hear Joel basically reinforce what Grahame Adams and I had worked out here at Queensland News. We have introduced a couple of his tools in our planning function. To sit with other planners doing similar jobs was of a benefit, as the cross-pollination of ideas is always advantageous. Thanks for the opportunity to be a part of the workshop.

John Kluver, Engineering Supervisor, Queensland News, Australia

We are flexible about your specific needs for outcomes from the course.

The most basic way is to present a standard course after a brief email conversation about goals and objectives. The courses are tried and tested and have been used to good effect worldwide in many maintenance situations.

The second and most common option involves a one-day site visit before the class. This visit allows me to add examples from your facility, adjust the verbal presentation to suit your needs, meet some key players, and see some of the unique problems you face.

involves a more extensive site visit (to be defined) a few weeks before the class. This extra time allows me to customize and add examples from your facility and adjust the verbal presentation to suit your needs. It is always good to meet some of the key players and see for myself some of the unique problems you face.

The third option is to conduct a maintenance audit survey that looks at all the aspects of maintenance, evaluates areas where improvements are possible, and slanting the training to the competencies needed to implement the upgrades uncovered in the survey.